Laser welding

MONTER INSTALL GROUP PIOTR BUJAK is a market-leading manufacturer of steel components. We produce a wide variety of custom steel parts for all industrial sectors. One of our core areas of expertise is welding. We employ modern technologies that guarantee high-quality welds, which is why we have expanded our machinery park to include laser welding. Thanks to automation in our production processes, we handle both large-series orders and individual production components. We manufacture parts based on customer-provided technical documentation or develop our own designs in accordance with the client’s specifications.

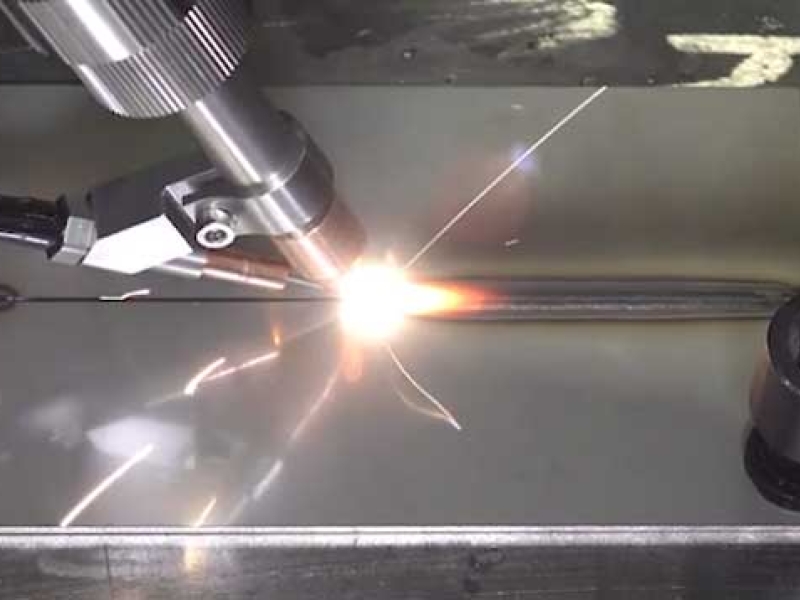

Laser beam welding, due to the high concentration and intensity of light energy, enables extremely precise and high-quality welds, which is why this method is gaining increasing popularity across many industries. Our laser welding service is performed using a 2000 W water-cooled laser.

Maximum sheet thickness for welded materials:

- CS: Carbon steel – up to 5 mm

- INOX: Stainless steel – up to 5 mm

- Al: Aluminum – up to 4 mm

- MA: Brass – up to 2 mm

Laser welding is one of the most advanced technologies used in metal processing. This method is growing in popularity due to its efficiency and adaptability to the demands of the modern market. At MONTER INSTALL GROUP, we specialize in laser welding, offering clients cutting-edge solutions that meet the highest standards. Equipped with an advanced machinery park, we carry out orders for the automotive, construction, energy, and many other industries. The high energy concentration of the laser beam produces welds that require no additional finishing while ensuring durability and aesthetic quality.

What is laser welding?

Laser welding is an advanced metal joining technology that focuses a high-energy laser beam onto the surfaces of the parts to be welded. This process enables strong, visually appealing joints across a wide range of materials, including carbon steel, stainless steel, aluminum, and brass. A defining feature of this method is its exceptional weld precision, which minimizes the risk of distortion and defects.

Laser welding – precision and innovation

MONTER INSTALL GROUP is a leader in steel component manufacturing, offering comprehensive solutions for various industrial sectors. One of our key specialties is laser welding, distinguished by its outstanding precision and weld quality. By utilizing advanced technologies—including a 2000 W water-cooled laser—we guarantee our clients the highest standards in metal processing. This modern method is used for both serial production and single components, allowing us to tailor our services to individual customer needs.

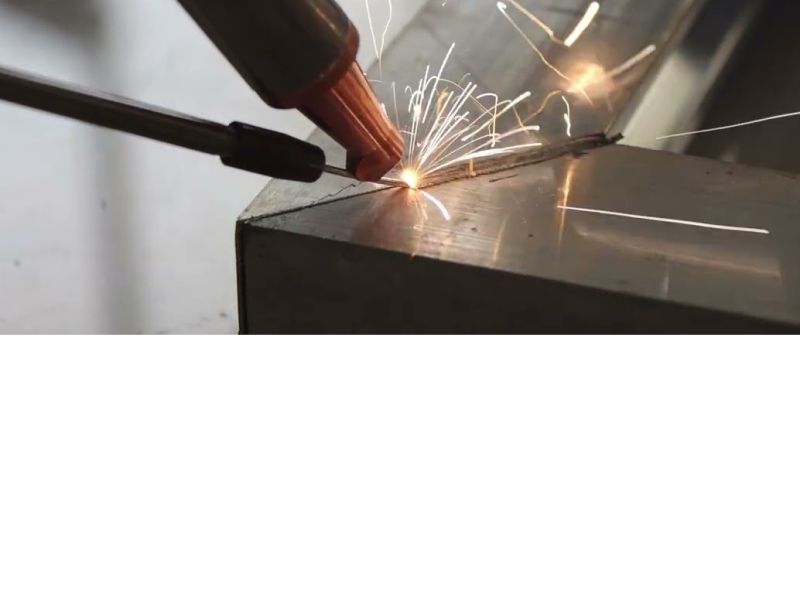

Moreover, MONTER INSTALL GROUP also offers manual laser welding, which provides greater flexibility when working with uniquely shaped components. Manual beam guidance enables precise adaptation to the client’s technical requirements, making this method ideal for single-unit and small-batch production.

Advantages of laser welding

Weld precision

One of the greatest benefits of laser welding is the exceptional precision with which joints can be created. The laser beam, with its small diameter and high energy concentration, enables very narrow and accurate welds. This precision allows laser welding to join even extremely thin sheets and delicate components without risk of damage.

Minimal material distortion

Unlike traditional welding methods, laser welding generates significantly less heat, resulting in minimal material distortion. Limiting high-temperature exposure preserves the material’s mechanical and aesthetic properties—critical in the automotive and electronics industries.

High weld quality

Laser-welded joints are exceptionally durable, aesthetically pleasing, and require no post-weld finishing. The high energy concentration of the laser beam ensures a very fast welding process, preventing porosity, cracks, or other structural defects.

Speed and process efficiency

Laser welding is one of the fastest methods for joining materials, significantly boosting production efficiency. The ability to automate the process further accelerates order fulfillment, especially for large production batches.

Ability to join dissimilar materials

Laser welding effectively joins a wide variety of materials that may be difficult to weld using conventional methods. This is particularly important in industries that use complex structures combining different metals, such as stainless steel and aluminum.

Laser brazing – an alternative to traditional methods

Laser brazing is a related technology used where strong, nearly invisible joints are required. By using a laser beam, it is possible to braze thin sheets and irregularly shaped components, further expanding MONTER INSTALL GROUP’s production capabilities.

Laser welding of aluminum and steel

Aluminum and steel are critically important industrial materials used in countless applications—from automotive to construction. Precise processing of these materials is essential, and laser welding is one of the most effective joining methods. At MONTER INSTALL GROUP, we specialize in laser welding of both aluminum and steel, delivering the highest quality and weld reliability.

Laser welding of aluminum requires special attention, as this material has a low melting point and high thermal conductivity, making it more challenging to process. Thanks to advanced laser technology, we produce welds of exceptional aesthetics and durability while minimizing distortion. Laser welding of steel—both carbon and stainless—creates extremely strong, corrosion-resistant joints suitable for the most demanding environments. We employ innovative technological solutions to meet our clients’ expectations, executing orders with the highest levels of precision and efficiency. Our experience and modern machinery ensure that laser welding of aluminum and steel is a fast, efficient process that delivers excellent results.

Industrial applications of laser welding

Thanks to its versatility, laser metal welding is used across numerous industries, including:

- Automotive – manufacturing body components, exhaust systems, and mechanical parts.

- Aerospace – creating lightweight yet durable components.

- Medical industry – precise joining of delicate surgical instrument parts.

- Electronics – welding small enclosures and components.

MONTER INSTALL GROUP provides end-to-end service—from design to finished product. Our modern machinery park and experienced team of specialists guarantee the highest quality. Every order is executed according to the client’s individual requirements, with technologies tailored to the project’s specific needs.